PLC & CNC Logic Writing

CNC programming software is essential for creating precise program codes and instructions that drive computer-controlled machine tools. Each unique part requires its own CNC program, reflecting the sophistication of modern CNC machines, which boast full-fledged PCs enabling extensive user interaction. These machines can be networked via Ethernet and RS232, and are compatible with various storage devices such as Compact Flash cards and USB drives.

PLC

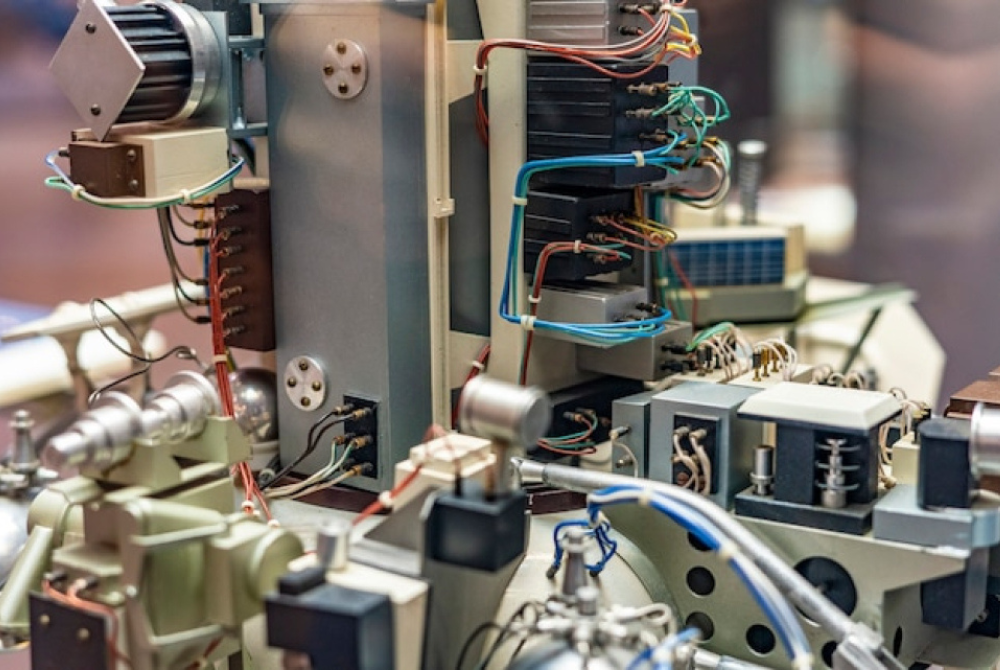

In parallel, Programmable Logic Controllers (PLCs) serve as ruggedized industrial computers, featuring inputs and outputs ranging from just a few to potentially hundreds through additional Input-Output (IO) modules. Inputs receive signals from sensors while outputs activate motors, valves, and other components via relays and switches. Operating on a sequential scan cycle, PLCs are crucial for controlling peripherals, interlocks, and signals in CNC machines. For instance, a PLC might prevent a chuck from clamping on a CNC turning machine while it’s in operation, showcasing the versatility of PLCs in automation tasks without the need for NC or CNC technology.